Plastics and polymers are by far the most expansive and variable materials that are marked with lasers.

There are so many different chemical compositions that you cannot categorize them easily.

Some generalizations can be made in terms of markings and how they will appear, but there is always an exception.

We recommend test marking to ensure the best results.

A good example of material variability is delrin (AKA Acetal).

Black delrin is easy to mark, providing stark white contrast against the black plastic.

Black delrin is truly an ideal plastic for showcasing the capabilities of a laser marking system.

However, natual delrin is white and does not mark at all with any laser.

Even the most powerful laser marking system will not make a mark on this material.

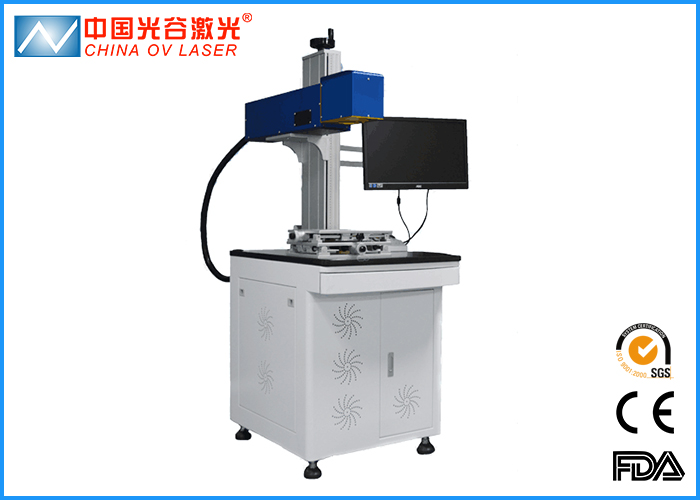

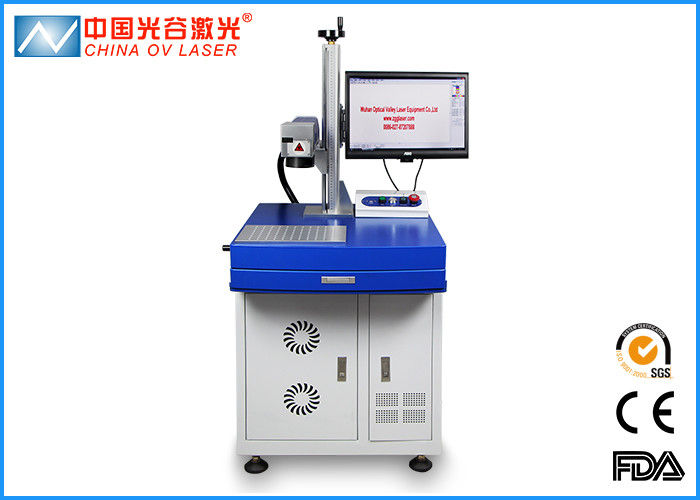

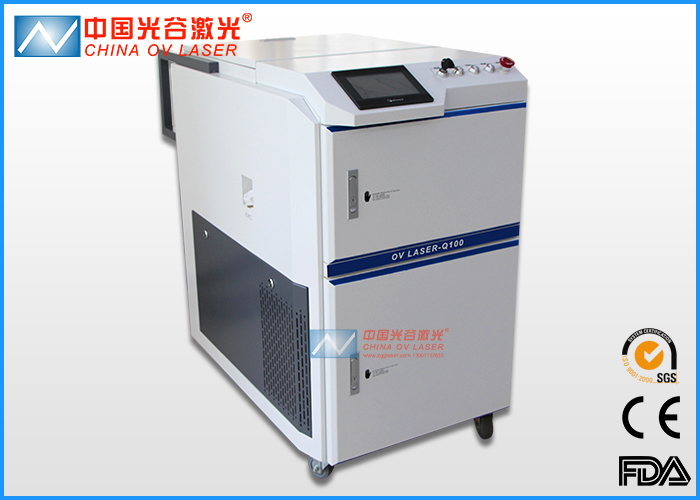

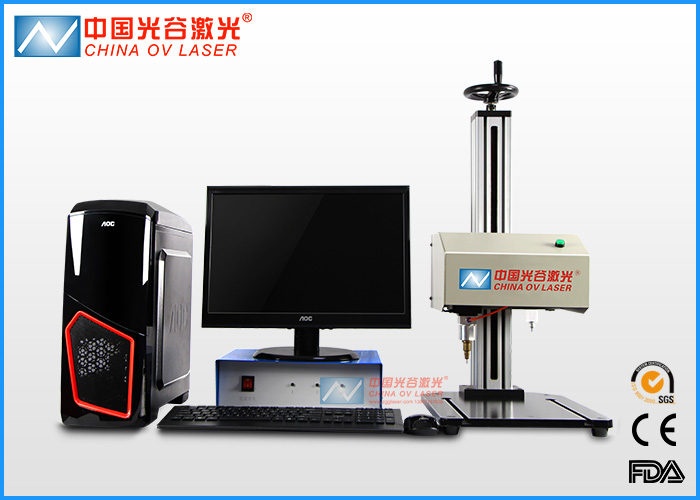

ZGG laser marking machine is capable of marking on plastics and polymers, the ideal system for your application depends on your marking requirements.

Because plastics and some polymers are soft and can burn while marking, Nd: YVO4 or Nd:YAG may be your best bet.

These lasers have lightning fast pulse durations resulting in less heat on the material.

532nm Green lasers can be ideal as they have less thermal energy transfer and also are better absorbed by a wider range of plastics.

The most common technique in plastic and polymer marking is color changing.

This type of mark uses the energy of the laser beam to alter the molecular structure of the piece, resulting in a change in the color of the substrate without damaging the surface.

Some plastics and polymers can be lightly etched or engraved, but consistency is always a concern.